The novel integrated system BONCUS will produce green gas from the bio-treatment of solvents that are released as waste during production (printing) by the flexographic industries. The conventional technology now is to burn the air with an regenerative thermal oxidizer (RTO), consuming high amounts of fossil energy, emitting NOx and emitting large amounts of CO2 to the air since there was no other solution.

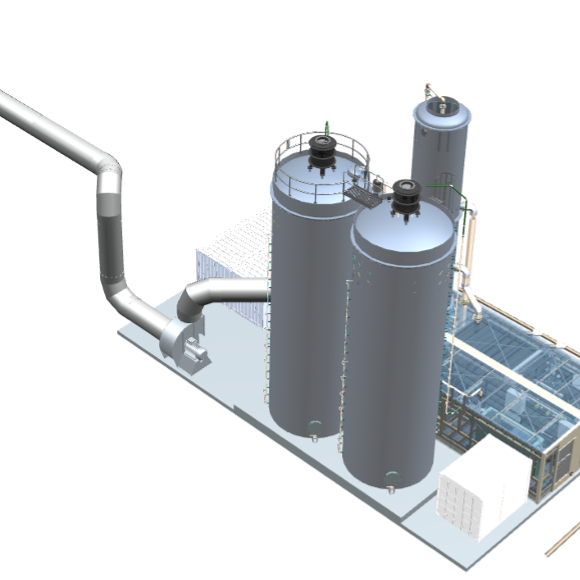

The BONCUS technology is unique in the world with this patented technology, developed in co-operation with the University of Valencia under two what is called now an Horizon Europe research and innovation grants in 2010. Patents, which are co-owned by the Company and the University of Valencia but with the commercial license exclusively with the Company, cover Europe and the Americas since 2015. The specific technology is referred to as ‘BONCUS’ and comprises a bioreactor facility (anaerobic bioscrubber) that is integrated in existing production processes. The relative GHG emission avoidance is 100%.

The pathway Solvent2Energy is using is the production and use of renewable energy at the company Trioworld Harlingen of 700,000 m3 of biogas annually from ‘waste air’. The flexographic industry produces waste air through solvents that are released in printing and in drying of the inks. The overall energy usage of Trioworld Harlingen in gas and electricity is replaced with green energy from the BONCUS by 75%. The absolute emissions reduction at Trioworld is 6.642 tonnes CO2 equivalent through the use of the BONCUS.

Instead of consuming a significant slice of the total energy consumption of the factory by treating the air emissions with an RTO, the BONCUS allows the (flexo)factory to us the solvents (mainly (bio-)ethanol) two times. Firstly use the solvents to print, and secondly to use the solvents as energy source for the production. Over-achieving with great ease the GHG emission goals of a 55% reduction for 2030 already in 2025.

The innovativeness lies in the fact that through the BONCUS waste air incineration in this sector is no longer necessary. The BONCUS technology is unique in the world with this patented technology, developed in co-operation with the University of Valencia.

The Solvent2Energy project aims to demonstrate a novel integrated system, the BONCUS, that converts solvents released as waste from an industrial printing proces into biogas through bio-treatment.

Currently, the flexographic printing industry operates as an energy-consuming procedure that produces pollutive air waste that comes from solvents released durng the printing and ink drying processes. In present circumstances, the solvent waste is disposed of via an incinerator destroying the solvents.

This BONCUS is installed in the Netherlands and has been rewarded with a Grant from the EU Innovation Fund of Euro 2.2331.000,- . It in the Call Innofund-2022-SEC and in the category Renewable Energy (RES).

The project is expecting to avoid 6.642 tonnes of CO2 equivalent. The project is started in 2024 and is anticipated to Entry into Operation on december 31st 2025.

The 3 project partners are:

- Pure air solutions BV (coordinator)

- Funs Skjinne Fryske Enerzjy BV

- Solvent2Energy Harlingen BV